Surface treatment

Teflon coating • Microporous surface • Rubber • Polyurethane

Surface treatment using fluoroplastics - Teflon

Fluoroplastics are often simply referred to as - TEFLON® (TEFLON is a registered trademark of DuPont company) and creating a fluoroplastic layer on the substratum is thus similarly simplified to - TEFLON COATING.

Thanks to a combination of unique properties (NONSTICKINESS - TEMPERATURE AND CHEMICAL RESISTANCE - SLIDINESS) these materials are irreplaceable and are being used across the entire spectrum of industrial production.

There are several basic types of fluoroplastics, known under abbreviations of their chemical names – PTFE (Polytetrafluorethylen), PFA (perfluoralkoxy - copolymer of tetrafluoroethylene and a perfluorinated vinyl ether), FEP (fluorinated ethylene - propylene), ETFE (ethylene-tetrafluoroethylene copolymer). Each type has slightly different features and is used for different applications. Therefore we deal with every inquiry individually and try to find the best possible solution of the surface protection. More information about properties nad types of fluoroplastics can be found on our blog.

You can find fluoroplastics under the brand name Teflon. Nevertheless, there are more brands and companies producing fluoroplastics. You may know Xylan for example. Should you need chemical resistant coating, you probably know Halar (E-CTFE).

Advantages of fluoroplastics (Teflon)

- Non-stick

- Chemical resistance

- Heat resistance

- Low friction

- Food contact

- Suitable for ATEX environment

Methods of applying fluoroplastic (teflon) surfaces

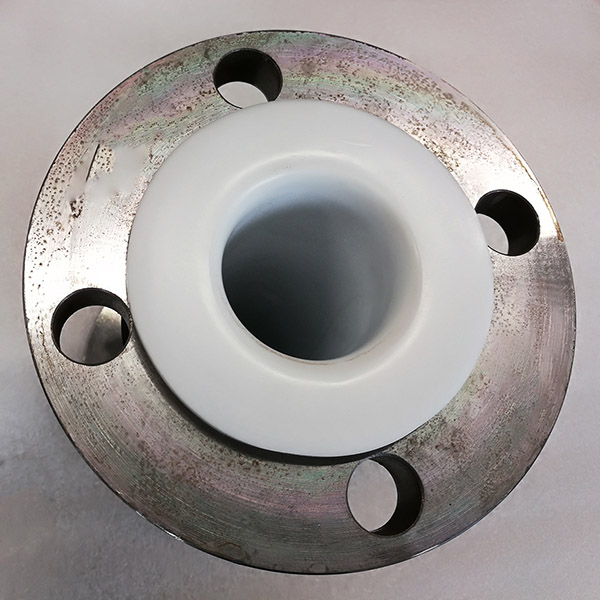

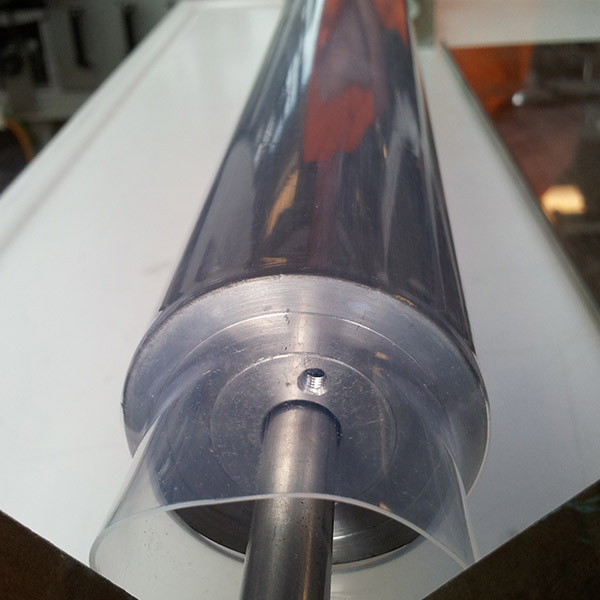

Teflon coating and rotational lining

Heat shrinkable teflon sleeves