Teflon coating and rotational lining

Applying a layer of fluoroplastics (teflon) on various parts and shapes.

Teflon coating

A layer of Teflon can be applied on parts in thicknesses up to several millimeters. The appropriate application method is chosen depending on the desired surface treatment, layer thickness, shape, etc. One of the methods is spraying - simply called as teflon coating (TEFLON is registered trademark of company Chemours). You can also read about Xylan coating or Halar coating - which are different brand names of other companies producing fluoroplastic coatings. This method is suitable for simply shaped parts where lower thickness is acceptable. Coating process consists of: entry parts inspection, degreasing (mostly thermal), grit blasting (parts can be partially masked), application of fluoroplastics, curing, quality inspection and packaging.

Use

Teflon coating can be used as a surface protection (e.g. anti-corrosion protection) or to improve properties of a surface (e.g. non-stick or low friction). It can be found inside of chemical tanks as a corrosion protection. Teflon is also applied on moulds for plastics or food industry where the non-stick property is required. You can read more about the properties of fluoroplastics on our blog. The use of teflon coating is almost unlimited and depends on the specific needs of our customers. You can coat rollers, but specially for them we offer more solutions as you can read in this article on our blog.

Teflon coating cannot be applied inside of variously shaped parts. This problem can be solved by using ChemResist.

Rotational linig ChemResist

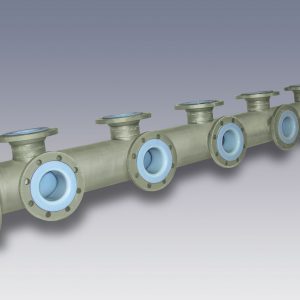

To apply fluoroplastic layer that is approx. 2 - 7 mm thick and inside of a shaped part is used technology called ChemResist - rotational linig provided by company Rudolf Gutbrod GmbH. Rotational lining is a technology where fluoroplastics are lined using high temperature and slow motion inside of a part. You can find more information about ChemResist in this article on our blog.

Main advantages of our solutions

- Efficient fluoroplastic coating with required properties

- Teflon surface extends the life of the entire part and reduces maintenance costs

- Robust protection against a range of chemicals

- Suitable for very complex shapes

Re-coating / restoration of surface treatment

Thanks to the possibility of repeated application of fluoroplastics (teflon), we are able to lower maintanence costs and also extend the life of the entire part. If the coating is already after its lifetime, it is not always necessary to make the whole piece again, but only re-coat the teflon layer. It is possible to recoat almost every type of coatng. We are also able pro mechanically repair the parts itself.

Check out the interactive picture showing the part before and after recoating. Use the mouse to see both phases of the process.

Rudolf Gutbrod GmbH

BALTRO GROUP, a.s. is the exclusive representative of company Rudolf Gutbrod GmbH in the Czech Republic, Slovakia, Poland and Baltic states. Rudolf Gutbrod GmbH is the european leader on the fluoroplastics coating market, they own unique know-how (CHEM-RESIST) a and hold several patents (TIC system, ICS system, Abrasion resistant PFA). Their research and development keep GUTBROD at the absolute pinnacle as a supplier of special anti-corrosion solutions for the chemical and pharmaceutical industries.

Direct layering of fluoroplastics

Using the technology of direct extrusion, a layer of flouroplastics may be applied on various profiles of diverse materials, in continuous (almost "endless") lengths. Products like - rubber cords and profiles, as well as steel flexible hoses may be coated with a fluoroplastic layer (PFA or FEP) of various wall thickness - according to customer's requirements.