- Contact us

- +420 722 420 199

- info@baltro.cz

ChemResist – unique solution for corrosion protection of inner surfaces

ChemResist

Unique solution for corrosion protection of inner surfaces

Solution description

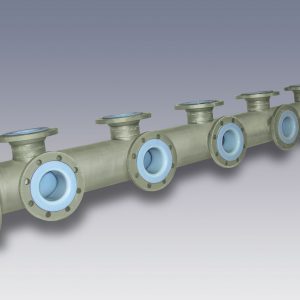

Rotational lining CHEM-RESIST® is a unique technology offered only by Rudolf Gutbrod GmbH with these parameters. Gutbrod is represented by BALTRO for the Czech Republic, SK, PL and the Baltic states. The uniqueness of this solution lies in the possibility of forming a layer of fluoroplastics (Teflon) in thicknesses of up to several millimeters (2-7 mm) on the inner surfaces of variously shaped parts. This is a huge advantage over layered Teflon coatings, which are applied in thicknesses up to 1.5 mm. Due to its excellent chemical resistance is ETFE most commonly used for rotational lining.

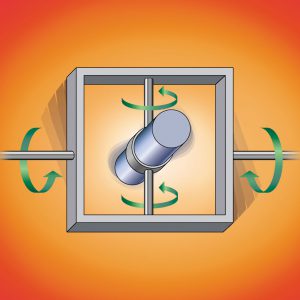

Rotational lining is a technology where fluoroplastic powder is transformed into desired layer on the inner surface using heat, slow rotation and centrifugal forces. This process results in an even distribution of the fluoroplastic on the inner surface of the entire part at a predefined thickness. There are no seams, welds, transitions, etc.

If you are interested in other fluoroplasting applications or other types of surface treatment, check out our offer of surface treatments.

Advantages of rotational lining ChemResist

Exceptional and versatile chemical resistance at high temperatures. Purity of used material - ETFE. Also available in electrically conductive design (ATEX). No tension in the surface. Resistant to solvents. It is easy to clean thanks to the anti-adhesive surface. Compliance with the FDA. Low temperature resistance. Also applicable for vacuum.